General Machining

We operate a complete machine shop that is capable of performing numerous machining functions to repair or manufacture small or large parts & equipment. Our highly trained Machinists are capable of providing expert technical support to repair or manufacture your metal parts to meet OEM or your specifications. For further information on our CNC/Manual lathes, mills, and other equipment capabilities, please refer to our PDF file titled CMP Equipment & Capacities List.

Services we provide:

- Turning

- Milling

- Boring

- Grinding

- Polishing

- De-burring

- Broaching

- Resurfacing

- Threading

- Heat Treating

- Facing

- Beveling

- Cutting

Industrial Pump Repair

Our Company specializes in repairing industrial pumps for water, sewage, and sump sludge applications. We manufacture or repair internal pump parts such as seal areas, bowls, housings, impellers, wear rings, casings, collars, shafts, and stuffing boxes. Our technicians utilize welding, flame spraying, machining, and coating technologies to replace or repair pump parts, significantly improving the efficiency of the pump.

Typical Pumps and brands we service and products we use:

- Submersible Pumps

- Split Case Pumps

- Multi-Stage Centrifugal Pumps

- ABS, Goulds, Godwin, Gorman-Rupp, Taco, & Worthington Pumps

- Coatings: Belzona & Chesterton

- Powders: Oerlikon Metco, Seaco, & Eutetic

- Wire: Oerlikon Metco

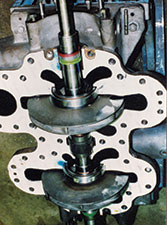

Flame Spraying/Metalizing

We spray a variety of metal alloy coatings that are applied by low or high velocity methods to obtain the highest quality coatings available in today’s market. In addition to the coating application, we offer machining, grinding, and polishing to complete the parts to meet your specifications. We utilize state-of-the-art Sulzer Metco Diamond Jet Equipment, powders, and wires to apply hard faced and high velocity ferrous and non-ferrous coatings to parts that require repair, such as: shaft bearing areas, spindles, pump sleeves, seal areas, rotary air housing units, and much more.

Advantages of flame sprayed coatings:

- No distortion of the part being coated

- Increased component life

- Improved performance

- Reduced part wear and erosion

- Reduced maintenance cost and downtime